Choosing the suitable printing method is crucial to create the high-quality materials and brochures you and your company need to promote your high-end items. The distinction between a good and a fantastic print ad campaign for high-end goods sometimes comes down to the effectiveness of the print medium.

A workable answer exists as a tried-and-true procedure for producing consistently excellent materials that will significantly maximize the sales of your high-end offerings. The solution lies in UV curing, but what exactly is that? What is its function in the printing industry?

What is Ultraviolet Light Emitting Diode (UV LED) Curing?

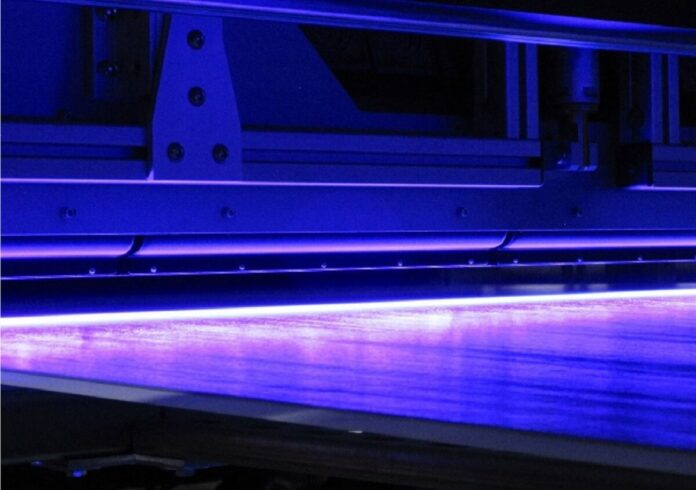

Through high-intensity electronic ultraviolet (UV) light, inks, coatings, adhesives, and other photo-reactive substances are transformed into an instantaneously fixed-in-place solid through the process of polymerization in a low-temp, high-speed, solvent-less photochemical process known as UV curing. By contrast, “drying” causes chemical solidification through evaporation or absorption. UV curing creates a strong bond between the cured substance and the substrate you applied to without leaving any tacky, sticky, or flaky residue behind.

Flood curing, spot curing, handheld curing, and conveyor curing are all UV curing methods. Mercury-based arc lamps produce broad-spectrum UV light, while light-emitting diodes (LEDs) emit only UVA energy and are used in UV curing systems. There is the option of using UVC LEDs, although these have significantly lower power output and efficiency.

For a long time, printing and some other industrial production methods have relied on mercury arc (HG type) lamps as the go-to UV curing method. They’re practical but have drawbacks. What’s most notable is that they use up a lot of power and heat a lot of space. Mercury-arc bulbs have a lengthy environmental impact. It would help if you disposed of them at a price and under regulatory monitoring since they produce ozone, necessitating exhaust systems to preserve air quality.

UV curing with LEDs has all the benefits of conventional UV curing and addresses many issues that arise during heat-set drying. They can switch on and off immediately, dry or cure quickly and evenly, produce little to no heat, and use little to no energy. Furthermore, LED UV’s compact size makes it a good fit for applications with limited room for expansion.

How the UV curing for printing works.

LED UV employs a novel drying technique known as UV curing, showing excellent results. UV light, rather than heat, quickly dries the ink. The turnaround time is reduced, and the ink’s rich color and high quality are preserved thanks to this method. Due to the faster drying period, LED UV utilizes about 20% less ink than conventional printing presses.

Because of the method’s ability to vastly enhance physical characteristics, your printed materials will have a professional-grade sheen.

Read Also: Printing Personalized Cereal Boxes for Selling New Caramel Flavor

With a little more detail, UV light comes from a specific region of the electromagnetic spectrum, specifically the region encompassing light with wavelengths between 200 nm and 400 nm. LED UV printing is related to this spectrum because the light immediately cures the inks, coatings, and adhesives used in the process. Other critical applications include water purification and semiconductor lithography.

IUV uses cutting-edge machinery and only the finest raw materials to create UV LED curing solutions tailor-made for your industry. With their extensive knowledge and training, they can supply only the finest LED UV curing equipment.

![Etruesports IOS App: Purpose, Installation Steps and Issues [Solved] Etruesports IOS App Purpose, Installation Steps and Issues [Solved]](https://www.articles4business.com/wp-content/uploads/2025/01/Etruesports-IOS-App-Purpose-Installation-Steps-and-Issues-Solved-100x70.jpg)